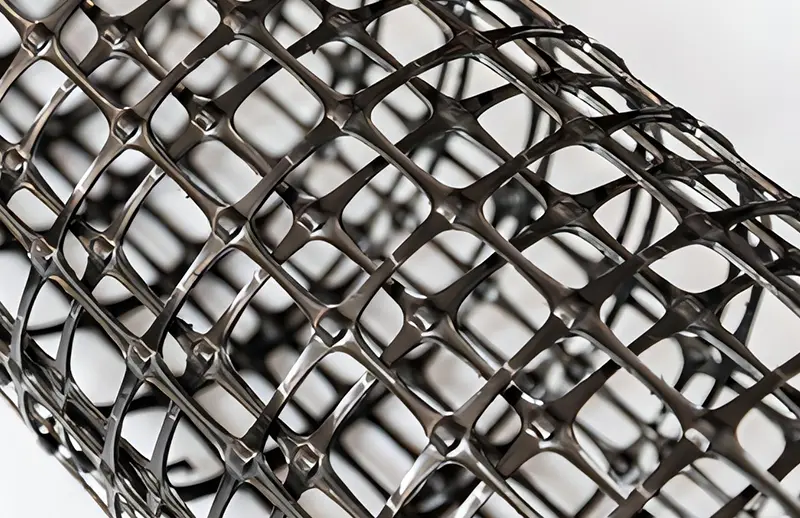

Woven Geotextile Fabric

High Tensile Strength Woven Geotextile Fabric Information

Weight : 100gsm – 800gsm

Width: 1m – 6m

Length: 50-200m

Material: Polyester

Woven Geotextiles are light weight, good water permeability, High tensile strength and corrosion resistance, they are the ideal material for geotechnical engineering.

It has high mechanical strength such as tensile resistance, tear resistance, puncture resistance, and puncture resistance.In stone slope protection, it can effectively prevent the impact of irregular stones on the cloth surface;Good elongation performance, fast stress dispersion and transmission;

Woven Geotextiles

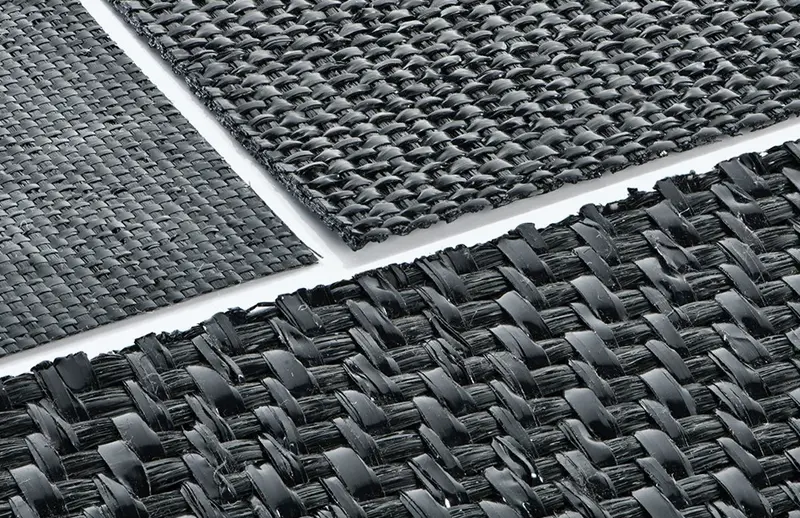

Woven geotextiles fabric production entails knitting fibers together either in a parallel or perpendicular orientation to one another. The weaving of fibers together results in a geotextile with improved modulus, high permeability and high tensile strength. They also have low elongation.

For situations where stabilizing and reinforcing soil is necessary, woven geotextile fabrics are the ideal choice. You can use them in construction of roads and embankments.

| Index | Unit | DK100 | DK150 | DK200 | DK300 | DK50S | DK65S | DK70S | DK100S | DK110S | DK120S | DK150S | DK200S | |

| Tension Strength |

Vertical | kN/m | 100 | 150 | 200 | 300 | 50 | 65 | 70 | 100 | 110 | 120 | 150 | 200 |

| Latitude | 50 | 50 | 50 | 50 | 50 | 65 | 70 | 100 | 110 | 120 | 150 | 200 | ||

| Elongation at Break |

Vertical | % | 9±1 | 9±1 | 11±1 | 11±1 | 9±1 | 9±1 | 10±1 | 10±1 | 10±1 | 11±1 | 12±1 | 12±1 |

| Latitude | 9±1 | 9±1 | 10±1 | 10±1 | 9±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 10±1 | 10±1 | ||

| Breaking Strength at 2% Elongation |

kN/m | 19/ 10 | 26/ 10 | 27/ 10 | 45/ 10 | 10/ 10 | 12/ 12 | 12/ 16 | 15/20 | 12/25 | 12/25 | 10/30 | 30/40 | |

| Breaking Strength at 5% Elongation |

kN/m | 50/30 | 75/30 | 80/28 | 110/28 | 30/30 | 35/35 | 37/40 | 47/50 | 50/55 | 50/55 | 55/80 | 90/ 100 | |

| Trapezoidal Tearing Strength |

Vertical | N | 900 | 1000 | 1500 | 1700 | 400 | 500 | 900 | 1000 | 1000 | 1200 | 1300 | 3000 |

| Latitude | N | 500 | 500 | 500 | 500 | 400 | 400 | 700 | 1000 | 1000 | 1200 | 1200 | 2400 | |

| Strong Grip | Vertical | N | 2000 | 2200 | 3000 | 3500 | 1300 | 1500 | 1900 | 2200 | 3000 | 2500 | 4000 | 4000 |

| Latitude | N | 1000 | 1000 | 1000 | 1000 | 1200 | 1400 | 1400 | 1600 | 1800 | 2200 | 3500 | 3700 | |

| Static Bursting Strength(CBR) |

kN | 6.5 | 7.6 | 8.5 | 9.5 | 5.0 | 5.0 | 7.0 | 11 | 11.0 | 12 | 14 | 18 | |

| Equivalent Aperture (O95) |

mm | 0.05–0.5 | ||||||||||||

| Vertical Permeability Coefficient |

cm/s | K ×( 10-2–10-5),K= 1.0–9.9 | ||||||||||||

| Mass Per Unit Area | g/m2 | 250 | 330 | 390 | 550 | 185 | 210 | 240 | 315 | 340 | 375 | 460 | 640 | |

Geotextile manufacturers make fabrics which can be used in various different areas which are:

For Civil Engineering purposes

The fabrics used in geotechnical applications, such as road and railroad embankments, earth dikes, and structures for coastal protection, are known as geotextiles. They are created to carry out one or more fundamental tasks, such as filtration, drainage, separating soil layers, strengthening, or stabilisation. As a result, practically all geotextile applications have multiple uses. Geotextiles are polymer fabrics used for a variety of civil engineering applications, including the building of highways, drainage, harbour works, breakwaters, and land reclamation.

For separation

Permeability and strength are two crucial factors in the selection of a geotextile for separation. The soil fines or sand particles must be retained while yet being able to pass through the geotextile used for separation. It should allow water to travel through it at a similar rate to the nearby soil or perhaps a little bit quicker. The lowest soil particle size must be retained without clogging or plugging. We must take into account the geotextile’s permeability, the subgrade and subbase’s grain size distribution, and its fundamental strength qualities when choosing a particular geotextile for separation.

Geotextile Materials

The frequently applied materials in the production of geotextiles are polypropylene and polyester. Still, subject to the intended usage, you may employ either synthetic or organic fiber in the geotextile fabric.

On that account, let’s discuss the common materials used in the manufacturing of geotextile membrane:

Natural Fiber

Bio-degradable natural fabrics have a short service life. They are often geotextile erosion control solutions till vegetation starts growing within an area. The common natural fibers used for geotextile membrane manufacturing include:

Jute

This is a flexible and highly decomposable fiber used to primarily make garden geotextile fabrics since they offer nutrients to plants after biodegrading. The quick decomposition of jute geotextile materials makes them have a shorter service life.

However, it is practical to extend these geotextiles lifespan close to 20 years by applying several treatments and mixing. This facilitates production of customized jute geotextile fabric having distinct permeability, tenacity, and pore size based on the location and project specifications.

Coir

These refer to 100% natural, decomposable geotextile fabrics manufactured utilizing coir yarn. The yarn comprises of coconut fiber, which is the most long-lasting natural fiber.

Coir Geotextiles shield landscape and encourage fast plant growth. Thus, they usually act as geotextile landscape fabrics to help in soil erosion control and renewing vegetation.

Synthetic Fiber

Synthetic fibers have always been the primary raw material utilized in the geotextile manufacturing. Majority of woven and non-woven geotextile fabrics are produced via needle punching process, which makes use of polymeric materials.

The following are the 4 polymers that are regularly employed in geotextiles manufacturing:

· Polyamide

Nylon 6,6 and nylon 6 are the essential forms of polyamides employed in manufacture of geotextiles. Though a popular fiber- forming polymer, polyamides are not favorites for geotextile fabrics. There cost and general performance makes them subordinate to other types of synthetic fibers for geotextile grid.

· Polyester

Polyethylene terephthalate (PET), normally referred to as polyester, is another valuable synthetic material applied in geotextile manufacturing. PET has high creep resistance coupled, exceptional tensile and it can withstand elevated temperatures. Even so, the fiber is not ideal for geotextile landscape fabric uses since it is prone to hydrolytic degeneration in soils pH greater than 10.

· Polyethylene

Polyethylene manufacturing can be in crystalline structure, which is a valuable attribute for fiber-forming polymers. Low-density polyethylene, linear low-density polyethylene, and high density polyethylene are the common polyethylene types. HDPE fibers are usually employed in geotextile weed barriers.

· Polypropylene

Polypropylene fibers find extensive use in geotextile membrane manufacturing due to their chemical inertness, acceptable tensile features, and low cost. There low density is an additional advantage that ensures reduced cost for every unit volume.

However, the primary disadvantage of polypropylene geotextile fabric is its inferior sensitivity to UV radiation. Additionally, its features can easily degenerate when exposed to high temperature settings and possesses poor creep attributes.

Physical Properties of Geotextile

Specific Gravity

Specific gravity is a comparison of the density of a geotextile material to the density of water. Geotextiles whose specific gravity is greater than that of water are denser and will sink in water. Those with a specific gravity less than 1 will float on water. For applications where buoyancy is key you have to consider the specific gravity of the material.

Thickness

Thickness refers to the distance between two opposite sides of a geotextile material, usually measured in millimeters (mm) or inches (in). Thicker geotextile products provide better strength and longevity in the desired areas of applications.

Stiffness

Stiffness characterizes the ability of a geotextile material to go back to its original shape after being exposed to external forces. You have to consider stiffness where your project is on an irregular surface.

Density

Density is the mass a geotextile material per unit volume. It is typically expressed in grams per cubic centimeter (g/cm³). Geotextiles with higher density have greater resistance to penetration and reduced pore spaces. Low density will offer your project increased porosity.