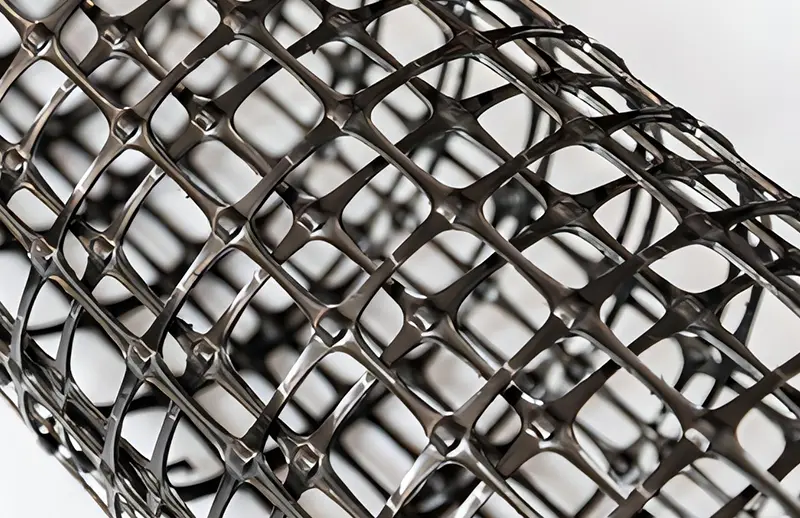

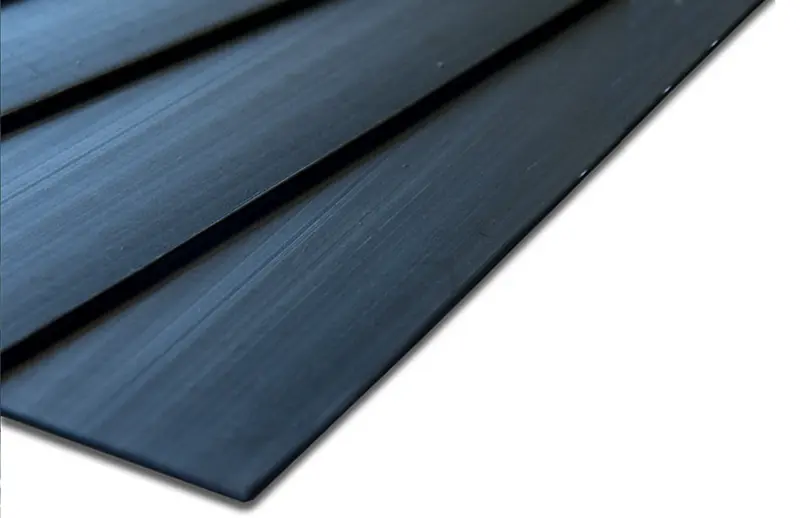

Smooth Geomembrane

Material: HDPE / LDPE /LLDPE/ PVC

Color: Black, White, Blue, Green (as request)

Standard: ASTM GRI-GM13

Thickness:0.2mm-3mm

Smooth Geomembrane, is a geosynthetic material with a flat and smooth appearance.

Material composition

Smooth Geomembrane is mainly made of high molecular polymers, such as high-density polyethylene (HDPE), through a specific production process. This material has excellent physical and chemical properties, such as high strength, corrosion resistance, and aging resistance.

Excellent waterproof performance: Smooth Geomembrane has extremely low permeability, which can effectively prevent the penetration of water and other liquids,ensuring the stability and safety of engineering structures.

Good chemical stability: The material can withstand the erosion of a variety of chemical substances, including acids, alkalis, salts, etc., and is suitable for various complex environments.

High strength and toughness: Smooth Geomembrane has high tensile strength and elongation at break, can withstand large stress and deformation, and is not easy to break.

Aging resistance: Due to the addition of auxiliary materials such as anti-aging agents, Smooth Geomembrane can maintain its stable performance for a long time and extend its service life.

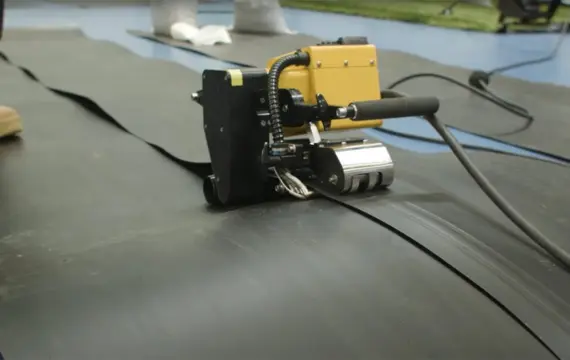

Welding Techniques Used in Geomembrane Installation

Welding is necessary during Installation of geomembrane lining systems, which needs to be conducted by a professional welder. The two common welding techniques applied during geomembrane installation are:

1, Double hot metal wedge welding

2, Extrusion welding

The most reliable and suitable method is double hot metal wedge welding. It is important to observe the following during geomembrane welding:

- Make sure there is o any foreign material or debris on the surface you plan to weld.

- When you employ extrusion welding, ensure to remove oxidation through grinding and clean the debris due to grinding.

- Use double welds which are helpful in forming air channel between the welds to enable testing.

- Regular make some trials welds to test the efficiency of the welding method.

| Properties | Test Method | HDPE-Smooth | ||||

| Thickness (min.ave.) | mm(mil) | 0. 5(20) | 0.75(30) | 1.00(40) | 1.5(60) | 2.0(80) |

| Density | ASTM D 792 g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 |

| Tensile Properties (min.ave.) | ASTM D 638 Tipo IV | |||||

| Yield Strength | /M(lb/in) | 7(40) | 11(63) | 15(84) | 22(126) | 29(168) |

| Break Strength | /M(lb/in) | 13(74) | 20(114) | 27(152) | 40(228) | 53(304) |

| Yied Elongation | % | 12 | 12 | 12 | 12 | 12 |

| Break Elongation | % | 700 | 700 | 700 | 700 | 700 |

| Tear Resistance (min.ave.) | ASTM D 1004 N(lb) | 62(14) | 93(21) | 125(28) | 187(42) | 249(56) |

| Puncture Resistance (min.ave.) | ASTM D 4833 N(lb) | 160(36) | 240(54) | 320(72) | 480(108) | 640(144) |

| Carbon Black Content | ASTM D 1603 (%) | 2~3 | 2~3 | 2~3 | 2~3 | 2~3 |

There is increasing application of geomembranes in several industries because of their versatility. Some of the sectors that register extensive use of geomembrane liners include:

1. Agricultural Sector – Farmers extensively use geomembrane liners in dam and pond lining since they offer reliable and cost-effective containment solutions. They also serve numerous roles in nurseries such as waterproofing and soil containment.

2. Mining Industry – Geomembrane in mining serve as lining solutions for tailing impoundments, heap leach pads, and evaporation pads. The geomembrane barriers prevent environmental pollution by hazardous chemicals from the mines.

3. Water Industry – There is immense geomembrane application in wastewater and drinking water treatment plants. The material prevents groundwater contamination when used to seal reservoirs, dams and canals.

Geomembrane liners are also valuable in avoiding potable water contamination by soil and other contaminants. It also hinders water loss via infiltration into the bordering soil.

Lining a canal or dam can reduce seepage, which enhances transportation and storage efficiency. Moreover, geomembrane linings also act as auxiliary containment for solar ponds, underground storage tanks, and brine solution.

4. Marine Industry – HDPE geomembranes find immense use in marine industry, especially in the building of jetty platforms or floating docks reinforced by pontoons. They give a protective barrier that elevates the longevity of the structure.

The HDPE geomembrane barrier guards the construction from destruction by environmental elements, marine life, and other pollutants inside the water. It equally provides the pontoon with extra buoyancy and avoids degeneration due to severe weather conditions, enhancing the general resilience of the pontoon.

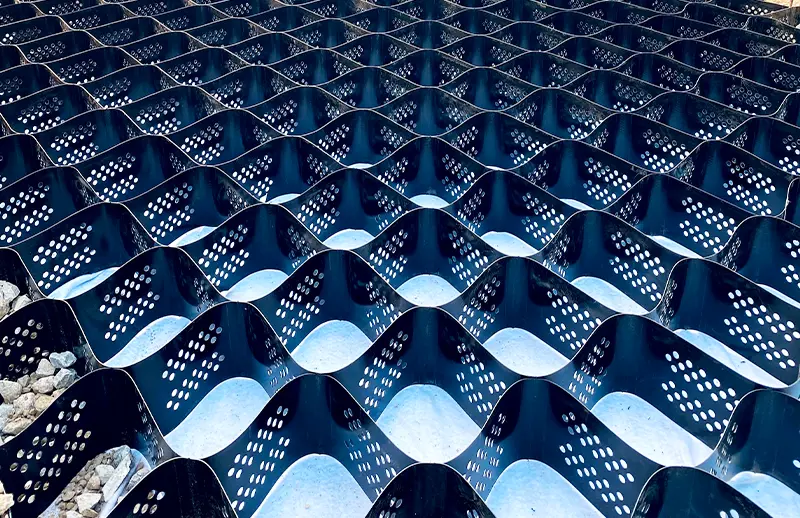

5. Solid Waste Management Sector – Use of Geomembranes for landfills include employing them as landfill coverings or closures, cut-off walls, and base liners for leachate and waste containment. Landfills often incorporate composite liners comprising of geomembrane and geosynthetic clay liner.

6. Civil Construction – Civil engineering projects immensely use geomembrane liners, from integrated drainage systems, tunnels to roads and dams. They are essential in quickening installation times and controlling expenses whilst safeguarding existing structures. Furthermore, geomembranes are applied in geotechnics industry to curb flow issues, deformation, and failure load.

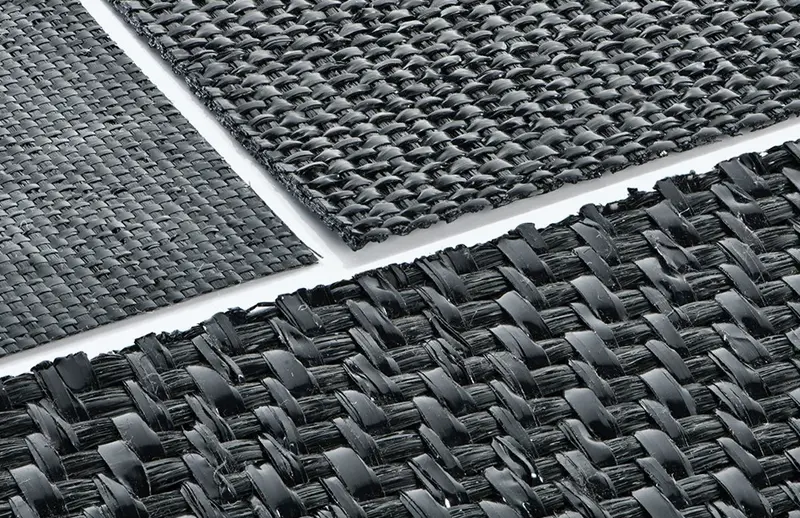

Difference Between Geosynthetic Clay Liner (GCL) and Geomembrane

The salient features of geomembrane linacers will influence their performance in specific applications. Let us briefly look at some of these properties in the table below:

Low permeability – Permeability is the quality of a material to allow gasses or liquids to penetrate through it. Geomembranes exhibit low permeability. This property is crucial in your applications where fluid containment is key such as lining landfill, ponds and reservoirs.

Chemical Resistance – Geomembrane are able to resist degradation when exposed to harsh chemicals such as acids, organic solvents and alkali. You can use them to contain chemicals that may cause corrosion to other materials

Flexibility – Geomembranes can be bent to several shapes without breaking. Their high flexibility makes them suitable for your projects on irregular surfaces and ground movements.

Durability – Geomembranes can withstand prolonged bending, puncturing, scraping and heavy loads. You can use them over a long time without fear of their deformation, frequent maintenance or replacement

Tear Resistance – Geomembranes can withstand mechanical stresses caused by high forces without tearing. This is crucial in applications where the geomembranes may be exposed to sharp objects or rocks.

Thermal Stability – Geomembranes can operate in environments with a wide range of temperatures without losing the integrity of their structure.

Light Weight – Geomembrane handling and transportation is effortless due to their light weight.

UV Resistance – Geomembranes can be designed to resist degradation due to exposure to UV radiation.

Weldability – Large sheets of geomembranes are easily joined together to create a continuous barrier.