The biogas tank is the main structure in the sewage treatment of livestock farms. It mainly stores and naturally treats the large amount of flushing water discharged daily from the milking parlor. The biogas tank uses the biogas tank geomembrane waterproofing method, and the traditional reinforced concrete self-waterproofing method In comparison, the advantages of the anti-seepage membrane are quick construction and low cost.

In terms of engineering application, the biogas digester geomembrane has the following advantages:

1. Simple construction: as long as the pond is dug and leveled accordingly, no concrete cushion is required;

2. Rapid construction: there is no solidification period required for structural concrete;

3. Resistance to foundation deformation: As HDPE film has good breaking elongation, it can resist foundation settlement or foundation deformation;

4. Good effect: this is the biggest feature of HDPE geomembrane;

5. Recoverable after use: This is the biggest feature of the biogas digester geomembrane. After use, it can be restored to its original state by simply putting it away and backfilling the tank.

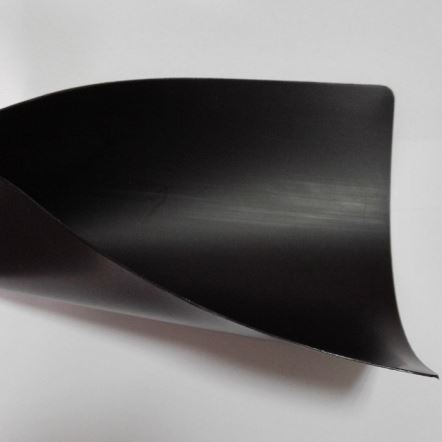

The design of the digester and the selection of geomembrane for the biogas digester require that the tank body has good anti-seepage performance to avoid pollution to groundwater. The digester has a simple structure, no special process holes and large internal surface area, and the soil quality of the construction site is single and broken. There are few sharp debris such as bricks, and it meets the requirements of geomembrane laying, comprehensive project requirements, project conditions and project location characteristics. Choose biogas digester geomembrane with a thickness of 0.75mm or more. In order to reduce welds and construction period, choose more than 6 meters. The width of the pool body is taken into account for the laying area of the pool body (1 meter circumference along the side wall), and 7% margin for overtime (anchorage, lap joint and missing welding part), as soon as possible after the completion of the construction of the biogas pool Inject water with a depth of about 0`8 meters to protect the geomembrane from being exposed to the sun and prolong the service life of the geomembrane. Especially in summer when the sun is strong, the open pool with no protective layer at the bottom should be paid more attention.

The finished surface of the construction is beautiful, and the biogas digester geomembrane has a good application effect in the large-area sewage treatment facility of the pasture. In view of its advantages of fast construction and low cost, it will soon be popularized and applied in the livestock industry.