People who do tunnel waterproofing have seen tunnel waterproofing boards. 99% of tunnel waterproofing boards are white. Why? What is the difference between a black board and a white board? Today I will explain the difference between the two.

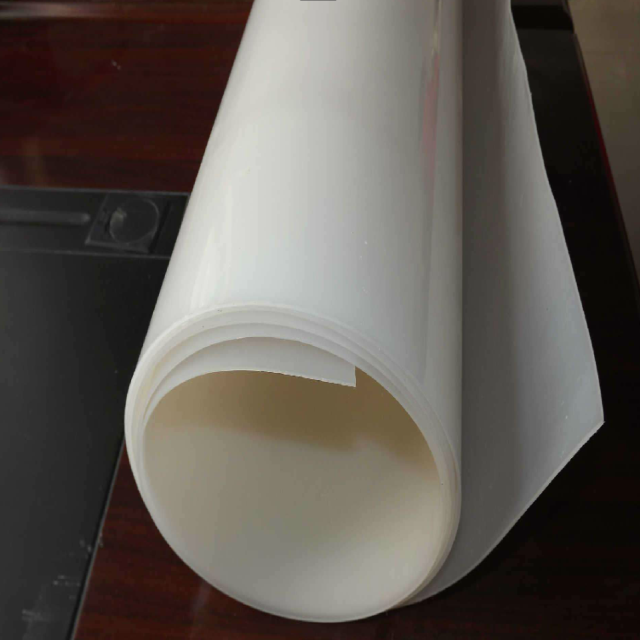

The raw material for the production of waterproof board is white plastic particles. Therefore, the production of waterproof board is generally white, especially for concealed projects. Then why are tunnel waterproof boards mostly white? This is related to the construction method of the tunnel waterproofing project and its environment.

In the tunnel waterproofing project, the laying of the tunnel waterproof board is mostly fixed with hot-melt gaskets. Its construction method is to first nail the plastic hot-melt gasket on the top of the tunnel with steel nails, and then weld the board to the gasket on the top of the tunnel. If the board is black, it will be troublesome in construction. The black board is basically opaque at all, so when it is hot melted, the position of the gasket cannot be seen clearly and can only be touched by hand, while the white waterproof board is different, because it has a higher transparency, so the construction staff will use the board. It is easy to see the exact position of the gasket, so it is very convenient to weld.

Moreover, the tunnel waterproofing project is in a dark place, without ultraviolet radiation, and the waterproof board will not be oxidized. The addition of black masterbatch during the production process will increase its production cost, so it is completely unnecessary.