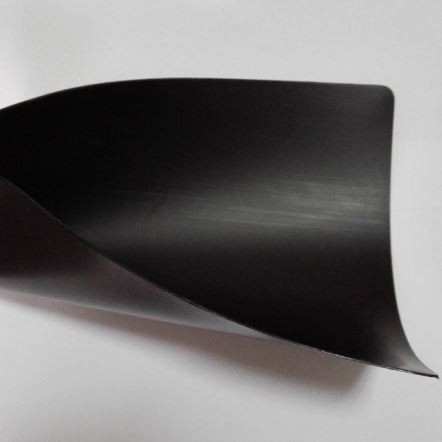

Comprehensive explanation of the effect of the use of anti-seepage membranes for fish ponds 2

Five: Weather requirements when laying anti-seepage membranes for fish ponds:

1. The temperature should generally be above ten degrees Celsius.

2. The wind should be below level 4.

3. When the temperature is too low, it is generally not recommended to construct and lay in strong winds above level 4 and rain and snow.

4. In windy weather, when the wind affects the laying of the impermeable membrane, the impermeable membrane to be welded should be pressed firmly with sandbags.

Six: How to lay the anti-seepage film for fish ponds

1. Before laying the bottom of the pond, check and measure the laying area. According to the measured data, transport the impermeable membrane with matching size to the corresponding position. When expanding the membrane, manually push it in a certain direction. Flat, straight, avoid wrinkles and ripples. The borders should be aligned neatly, and the two panels that need to be welded should be overlapped, and the overlap width should be controlled at about 15 cm.

2. Before laying the slope of the pond, check and measure the laying slope. According to the length and width of the material, transport the impermeable membrane to the anchoring ditch platform. When laying, push it from top to bottom according to the actual conditions of the site. The way. It should be extended from the high position to the bottom, and at the same time, it should not be pulled too tightly, and a margin of 5% should be left to prepare for local sinking and stretching. During the rolling process, it should be stretched and flattened in time to fit the slope surface and be smooth, without protruding folds. The fan-shaped area should be cut reasonably so that the upper and lower ends are firm.

Seven: Fishpond impermeable membrane bonding method

Before the fish pond membrane is bonded, use a towel to remove the sand, soil and other dirt on the membrane surface to ensure that the membrane surface is clean.

1. Hot melt welding method:

Before hot melt welding, the upper and lower layers of impermeable membranes must be overlapped by 15 cm. The welding process is divided into: adjusting pressure, setting temperature, setting speed, welding seam overlap inspection, installing film into the machine, and starting the motor. The welding seam is required to be neat and beautiful, and there must be no slip welding or skipping phenomenon. The welding temperature, speed and pressure are determined after experiments and inspections. The edge of the weld seam located on the upper impermeable membrane should be polished to an inclination angle to improve the welding quality of the weld seam. During thermal welding, the overlap width shall not be less than 15 cm. The thickness of the weld shall not be less than 1.2 times the thickness of the film. At the edges of the folds, cut the wrinkles of the cracks to ensure flat overlap. When squeezing the cut part of welding crack or wrinkle, the overlap should not be less than 10 cm. Cross lap joints should be avoided, and T-shaped staggered welding should be used. The welding seam is required to be neat and beautiful, and there must be no slip welding or skipping phenomenon.

2. Adhesive bonding method: It is not recommended to use the adhesive bonding method for large-area construction of anti-seepage joints of fish ponds. Adhesive bonding method can be used to connect only at the corners or with the cement wall of the building. The joint strength of this method is too low, only about 40% of the strength of the base material of the impermeable membrane, and the adhesive will be reduced at 5 o'clock Adhesion. As a result, the seams cannot be stuck, and the anti-seepage requirements cannot be met. Although it is convenient to use hot-melt adhesive for bonding, it is afraid that gaps will appear at the interface when soaking in water all the year round, and the anti-seepage effect will be lost.