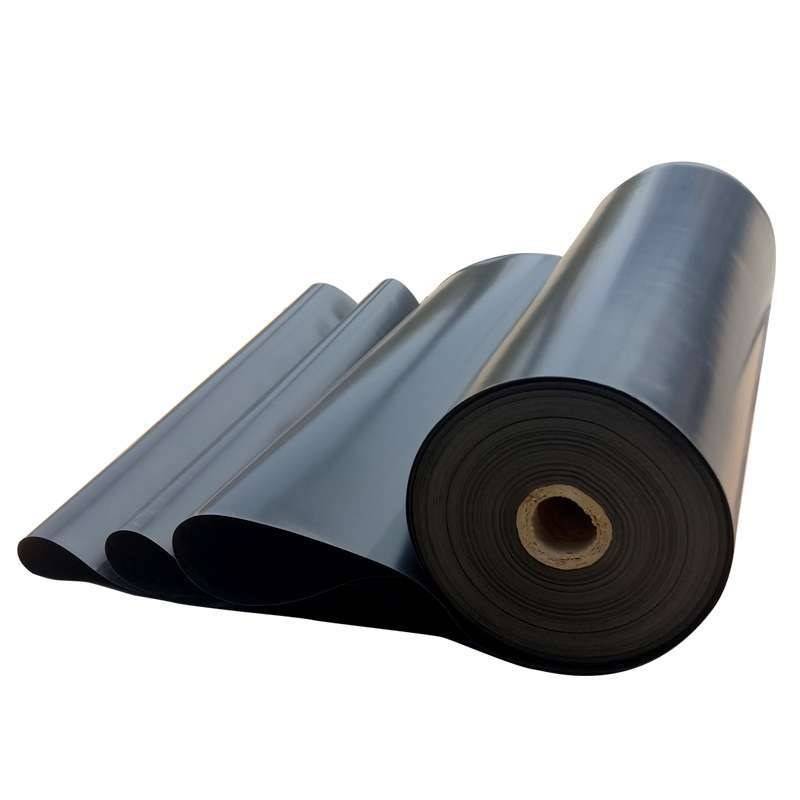

Smooth membrane HDPE liner, also known as smooth HDPE geomembrane liner, is very low permeability synthetic membrane liber or barrier with smooth surface. This kind of geosynthetic material is both rough and flexible. The smooth membrane HDPE liner is extremely cost effective and the preferred products for lining projects requiring low permeability, exceptional chemical and ultraviolet resistance properties. It is widely used across a variety of industries including waste containment, aquaculture, industrial project, water containment,energy project and mining project, etc.

Case study

Location: Australia

Product: Smooth Membrane HDPE Liner

Purpose: Reservoir

Problem: There is serious water seepage at the bottom of the reservoir.

The Australian client wanted to build a reservoir to provide irrigation and domestic water for the surrounding farmland. After a detailed survey to determine the construction location of the project, it was found that the local soil is sandstone-filled, with deep cracks, crisscrossing cracks, and large soil gaps. , And there is rock mixing, the project leader and related team members conducted infiltration experiments according to local conditions. This kind of soil is difficult to retain water and will penetrate directly into the soil through cracks and crevices.

In addition to local climatic factors, the local climate is temperate continental climate with less precipitation, coupled with high summer temperatures, and increased evaporation. The mountains in eastern Australia blocked it, and water vapor from the ocean was also difficult to penetrate into the interior of the continent, which also caused inland drought.

Taking into account various local factors, the key to reservoir construction is to prevent leakage at the bottom of the reservoir. The construction of the reservoir has also played a vital role in local life and production.

Based on the results of these investigations, the client hopes to find an ideal impermeable material to solve this problem and keep the water in the reservoir. After the customer found us, we also arranged a remote meeting between the counter and the customer. According to the client's budget, we have formulated an anti-seepage plan for the client.

Smooth film HDPE liner used in the Australian reservoir project

Smooth film HDPE for Australian reservoir project

Dingkun solution

According to the client's permeability test results and on-site survey results, there are large-scale cracks in the alluvial layer at the bottom of the reservoir. Address investigation revealed that the clay layer on the top of the foundation was highly cracked, making the ground unable to retain water. On the advice of DKM technicians, the customer chose a smooth geomembrane HDPE lining with a thickness of 1.5mm to prevent water from penetrating into the reservoir. DKM HDPE geomembrane lining is added with anti-ultraviolet, anti-aging agents and other additives in the production process, which greatly improves the service life of the geomembrane. In addition, DKM HDPE geomembrane has good puncture resistance, which can effectively prevent damage to the geomembrane caused by small rocks and allow moisture to penetrate.

The anti-seepage use DKM HDPE geomembrane is laid on the bottom of the reservoir and welded with DKM 900 series welding machine. The corners and T-shaped welds are treated with DKM 610A extrusion welding torch to ensure that the connection is firm enough to prevent leakage. Customers hope that we can deliver as soon as possible, help them solve the problem of water leakage in the reservoir as soon as possible, and quickly confirm the order with us.

benefit

The HDPE lining of DKM smooth film is made of high-quality polyethylene resin as raw material, added with carbon black, anti-aging agent, anti-ultraviolet absorber, stabilizer and other auxiliary materials, and adopts world-class automatic geomembrane production equipment through three-layer co-extrusion It is produced by blow molding or calendering technology, which is an effective waterproof barrier type engineering material.

Generalize

Glossy HDPE lining is a kind of waterproof barrier material based on high molecular polymer. The geomembrane liner with a thickness greater than or equal to 0.8mm can also be called a waterproof board. The main mechanism of the construction site is to block the leakage channel of the earth dam with an anti-seepage plastic film, which has high tensile strength and elongation, can withstand water pressure and adapt to the deformation of the dam body.

Geomembrane has the advantages of small permeability coefficient, large elongation, good environmental protection benefits (compared to concrete and clay materials for seepage prevention), light weight and softness, convenient construction, strong regional adaptability, high factory production quality assurance rate, and more convenient use. Operation and maintenance. In the field of anti-seepage, geomembrane has a wide range of applications, from roof waterproofing to dam anti-seepage. And in recent years, with the development of geomembrane material science and the improvement of geomembrane performance, the application of geomembrane has become more and more extensive, and the scale of use has become larger and larger. In some large-scale water conservancy projects, such as dams, reservoirs, dikes, etc., the application prospects of geomembrane are very good. Geomembrane is more and more favored by engineering personnel due to its advantages of easy construction, short construction period, and low cost.