1. The essential difference between geocell and geogrid

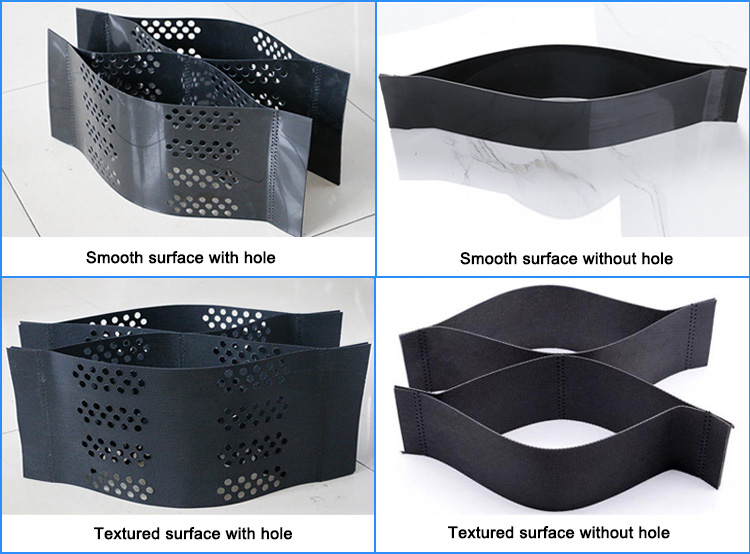

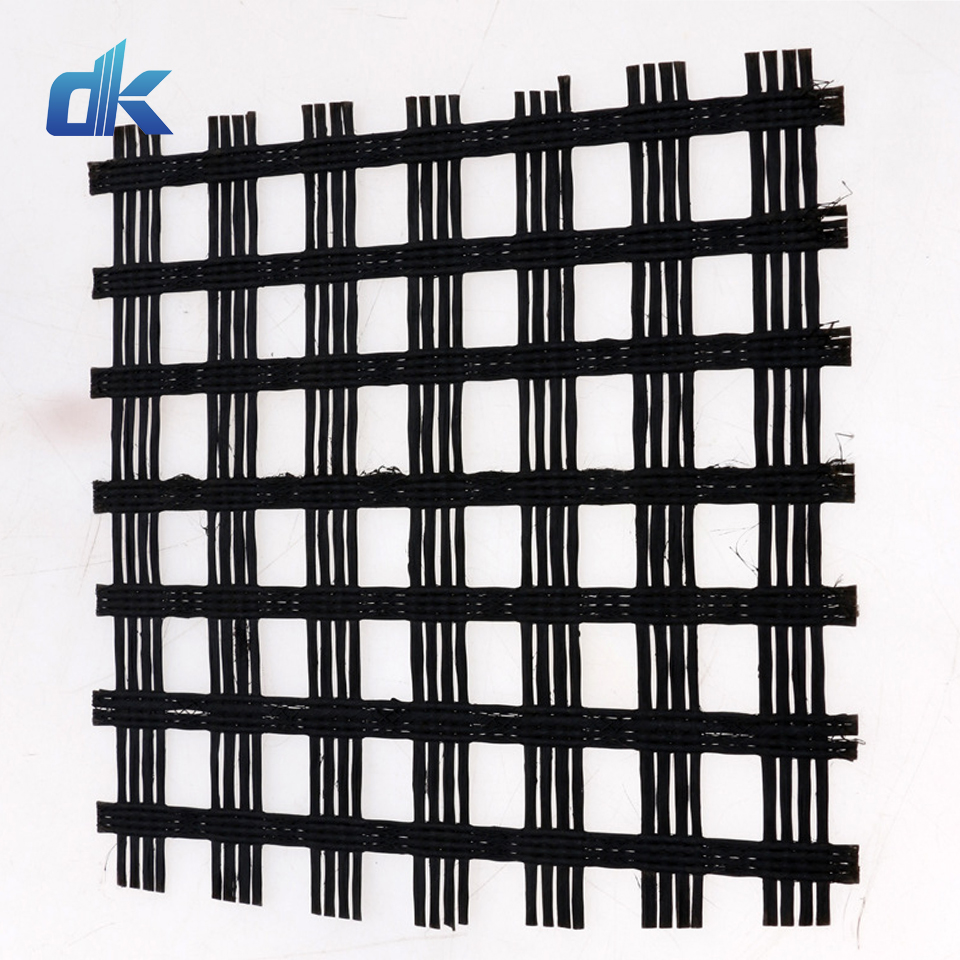

From the perspective of professional production, the geocell is a three-dimensional mesh structure cell structure produced by reinforced HDPE sheet raw material through high-strength electric welding. Geogrid is a two-dimensional grid pattern or a three-dimensional grid pattern screen grid with a certain aspect ratio, which is made of polymer materials such as polypropylene and polyethylene through thermoplastic or compression molding. Both are made of lightweight polymer materials, and are widely used in a series of soft ground treatment foundation reinforcement, retaining walls and ground cracking fiber projects such as pavement construction.

The comprehensive difference

1. In terms of brand image from the perspective of structural mechanics, geocells are three-dimensional reinforcement geogrids that are planar reinforcement.

2. In terms of shape and structure, the geogrid is a three-dimensional grid structure. The geogrid is a two-dimensional grid or a three-dimensional grid with a certain height-to-width ratio.

3. In terms of comprehensive ability comparison, lateral restraint and bending stiffness: geocell is better than geogrid; bearing capacity and distributed load function: geocell is better than geogrid; ground anti-skid, anti-deformation ability: geocells are better than geogrids.

4. In terms of economic cost, both are of high quality and low price, and the geocell is slightly higher than the geogrid.

Geocell Features

1. It can be large or small, transportable and collapsible. During construction, it can be prestressed and stretched into a network structure, filled with loose materials such as soil, gravel, concrete, etc., to form a strong side restraint and large bending stiffness.

2. The material is light, wear-resistant, stable in chemical properties, resistant to light and oxygen embrittlement, and corrosion-resistant. It is suitable for soil conditions such as different soil layers and deserts.

3. Higher side limit and anti-slip ground, anti-deformation, effectively improve the bearing capacity of subgrade engineering and the effect of distributed load.

4. Changing geometrical specifications such as geocell height and welding distance can meet the needs of different projects.

5. It can be large or small, and the transportation volume is small; the connection is convenient and the construction speed is faster.

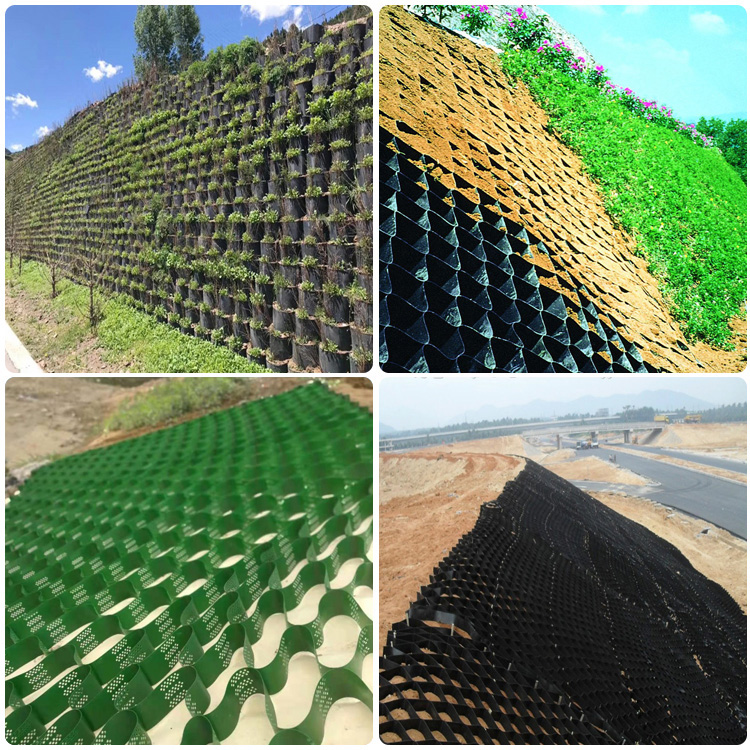

The main purpose of geocell

1. It is used to stabilize road and railway foundation projects.

2. It is used for river embankment and shallow water area river improvement projects to bear the load.

3. A mixed teaching retaining wall used to prevent landslides and loads.

4.When encountering soft ground. The use of geocells can greatly reduce the labor efficiency of construction, reduce the thickness of the subgrade, and the construction speed is faster, the performance is good, and the project budget is greatly reduced.

Geogrid is a two-dimensional grid-shaped grid made of polymer materials such as polypropylene and high-pressure polyethylene through thermoplastic or compression molding. When it is used in professional construction, it is called geogrid. The geocell structure reinforced subgrade is a foot-operated sandy soil structure reinforcement method, which does not change the basic wood characteristics such as the particle composition of the filler and the interconnection. Geocell mainly achieves the purpose of structural reinforcement through the mutual effect of the two bodies. The mutual effect mainly includes three aspects: the side restraint effect of the geocell, the net effect of the geocell, and the geotechnical The contradictory effect of the cell.