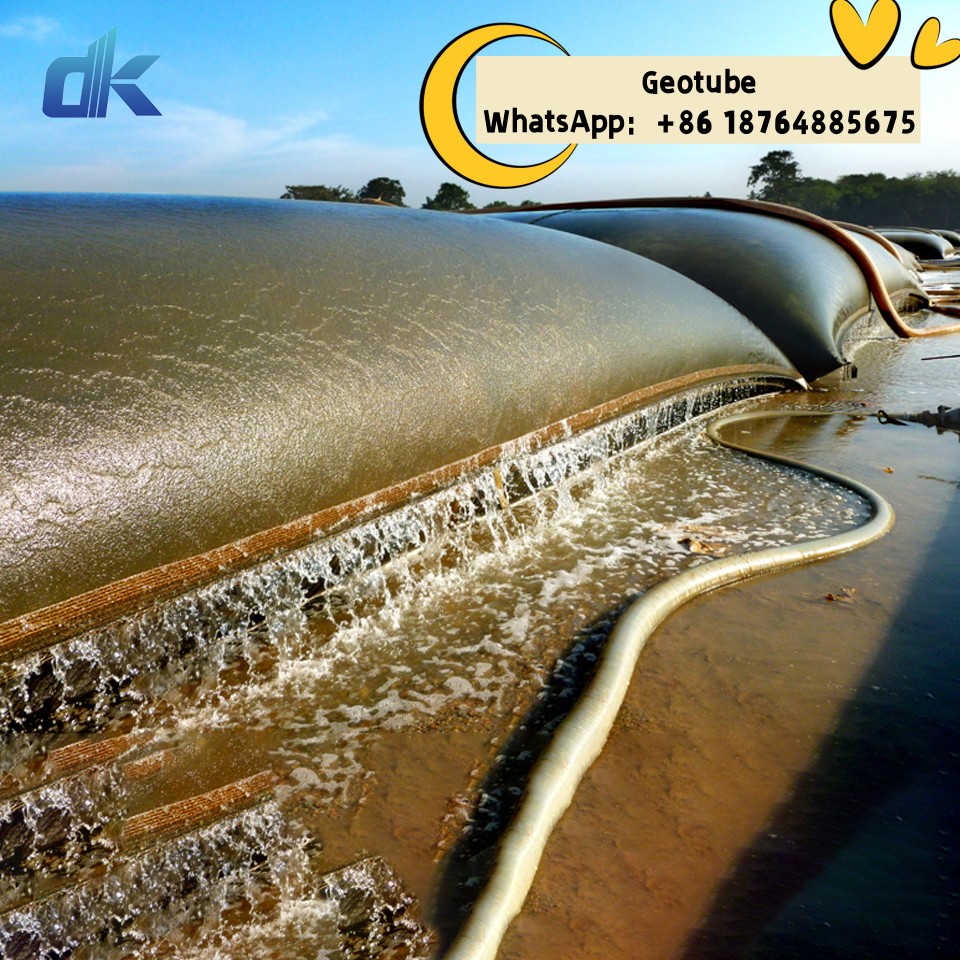

Geotube technology for dehydration steps:

Step 1: Fill

The sludge (slurry) is pumped into the Geotube container. Eco-friendly polymers are added to the sludge to bind the solids and separate the water. GeotubePP high-strength geotextile limits the outflow of silt.

Step 2: Dehydration

The clear water in the Geotube drains through small holes in the specially designed geotextile. Volume reduction allows repeated filling of the Geotube. The solids are retained in the geotube and the collected filtered moisture can be recirculated through the system.

Step 3: Integrate

After the last cycle of filling and dewatering, the solids remain in the geotube and continue to densify from drying as residual water vapor escapes through the fabric. Volume reductions can be as high as 90%. Once filled, the Geotube and contents can be deposited in a landfill, left on site, or the solids can be removed and applied to land in due course.